Why is my epoxy resin still soft or sticky?

Why hasn’t my epoxy resin cured?

There’s a number of reasons that your epoxy project might not have set (fully cured). We look at the different reasons why this might happen and what you can do to fix it.

Incorrect ratio of resin parts

Epoxy resins are made of a part A and part B. When mixed together the chemicals in both parts react to form a very strong finished product. Most general purpose epoxy resins will be a ratio of 1:1 which means you need the same amount of part A as you do part B (e.g. if you pour 100ml of part A, you will need to mix it with 100ml of part B).

Always check your resin though as some epoxy resin brands, especially those that are ‘Deep Pour’, may have a 1:2 ratio. This means for every 100ml of part A, you will add 200ml of part B.

Some resins will be measured by volume and others by weight. When weighing your resin, we recommend using kitchen scales like these as they are really accurate and can measure in ml or g. Just make sure you put your cup or jug on your scales first then set them to zero so you’re not calculating any extra weight.

Resin not mixed long enough

Once you’ve got the right amount of resin, you need to make sure it is really well mixed so that both parts are combined to activate their chemical reaction. When you mix your two parts, you will notice your resin either goes cloudy or streaky. You want to make sure you’re mixing for long enough so that your liquid is crystal clear (you may still have bubbles at this point, don’t worry too much about this).

Mixing in smaller batches can help make sure your resin is mixed together really well. You want to be able to reach the bottom and sides of your container so that you’re scraping any resin that has settled and ensure its all mixed together.

If you are mixing larger batches, an electric resin mixer is recommended as it will help get a good flow of resin and make sure nothing is missed. It can also save getting really sore arms!

Most resins in a moderate batch size will take 3-5 minutes to fully mix. This will depend on how thick your resin is. The thicker the resin, the harder it is to mix. I suggest mixing until clear, leaving for a few minutes then giving a final stir.

When you pour in to your moulds, you should have mixed well enough to make sure the bottom of your container isn’t out of ratio but if you start to see streaky or cloudy resin, make sure you either leave it out or give your poured resin a good mix in your mould. This issue can often be the cause of uncured resin if you have smaller projects on the go.

Too much pigment or colour for your resin

Adding too much alcohol ink, mica powder, pigment paste or materials like sand, can all impact how your resin sets. As a general rule, you want no more than 5-10% colour to your mixed resin. So if you have 100ml of resin, don’t add more than 10ml of colour or pigment.

Adding alcohol ink directly to clear resin without mixing, can also impact how your resin sets. You can add a top coat resin or second layer over your colour to reduce sticky alcohol ink layers.

Air temperature and resin

Most resins will perform best at around 25 Degrees Celsius / 77 Fahrenheit. If your air temperature is lower than this, there are a few things you can do to help:

- If you keep your resin in a cooler space like garage or shed, bring it indoors to a warmer room before you pour and mix

- Use a fan heater to warm up your work space

- Warm your part A and part B bottles in a bowl or sink or warm (not hot) water for 10 minutes before you measure and mix them

- Use a resin heat mat. These mats sit under your resin mould and ensure they keep your resin at a higher constant temperature. They can reduce your curing time by quite a few hours too. Check out our blog on heat mats for more information.

Longer resin cure times

Each brand and type of resin will have varying cure times. Always check the instructions on your bottle but as a general guide:

- General purpose resin – 24 hours cure time

- Deep pour resin – 24-72 hours

- Fast cure resin – 12 hours

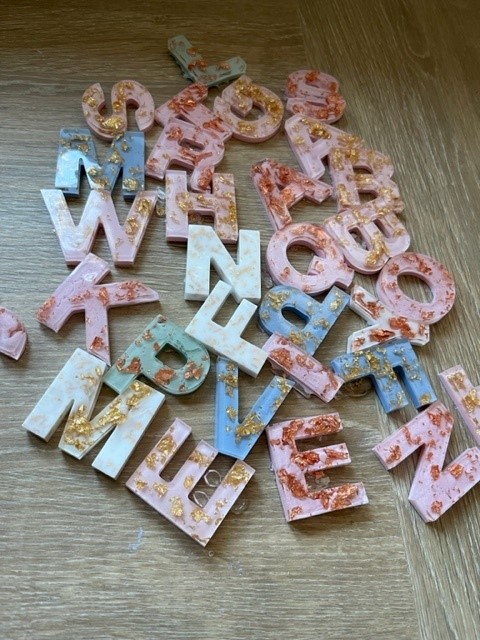

Some resins can take up to 30 days to fully cure. This is especially the case for smaller or thinner projects. As the chemical reaction between the two parts of resin creates heat and speeds up the curing time, if there is less resin, the chemical reaction may be slower and so will the cure time. Things like thin book marks, plates and bows, cake stands etc. can be softer for a good few days. Always take care when storing them and for flat things, make sure you don’t stack them until you are certain they are cured.