How does Epoxy Resin compare to Eco Resin like JDiction ResinCrete and Jesmonite? What is the difference and which is better value for money?

Are you thinking about trying an Eco Resin or want to know how its different to Epoxy Resin? We’re going to talk you through the differences between the two.

What is the difference between Eco Resin and Epoxy Resin?

Epoxy resin and eco resin are two different forms of resin, each with different uses and their own unique benefits. We’ve taken a look at how eco resin compares to epoxy resin and which type you might want to choose for your project.

It is worth keeping in mind that there are multiple different types and brands of both types of resin. We will save that breakdown for another blog.

Composition

Epoxy Resin

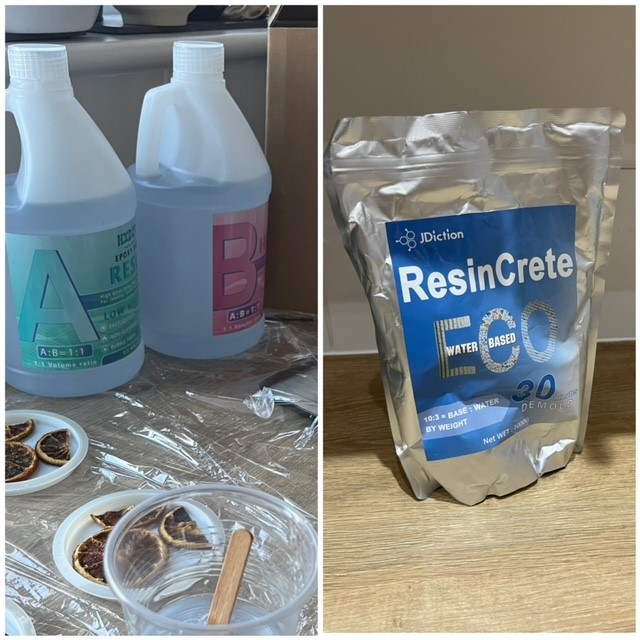

These resins are a type of polymer that forms a solid, durable material when mixed with a hardening agent. They will usually come in two parts: Part A and Part B or Epoxy Resin and Hardener. Depending on the brand of epoxy resin you choose and type (e.g. fast cure, deep pour, general use), you’ll have on average a working time of 30-60 minutes. Working time is the amount of time you have from mixing the two parts together to it starting to set – i.e. the amount of time you have to add your colours, pigments and add-ins.

Eco Resin

“Eco resin” is a broad term that may refer to resins formulated with environmentally friendly or sustainable materials. These resins may be derived from renewable resources, have lower VOC (volatile organic compound) emissions, or prioritize eco-friendly production methods.

Eco resins like ResinCrete are a powder that you simply add water to in order to create your mixture. Brands like Jesmonite, come in a two-part system where you add a special liquid to the powder to activate your resin mix. Your working time for eco resin is usually a little shorter than epoxy resin and you’ll get between 20 and 30 minutes.

Environmental Impact

Epoxy Resin

Traditional epoxy resins may have environmental concerns due to the potential release of VOCs during curing. They may not be suitable for use around animals or children because of this and you will need to use additional protective measures such as a respirator mask. However, there are many epoxy resins that you can purchase now that are low or no VOC’s and non-toxic.

Eco Resin

Aiming to minimize environmental impact, eco resins use sustainable ingredients, have no VOC emissions, and adopt eco-friendly manufacturing practices. These resins are often considered more environmentally conscious alternatives. Eco resin is easier to clean from your materials like cups, mats and stirrers too. This means that you can reduce your environmental impact by easily re-using your equipment just with soap and water unlike epoxy resin which requires sprays or single use plastics.

How can eco resin and epoxy resin be used?

Epoxy Resin

Widely used for various projects, epoxy resins can be great for things like coating surfaces, casting, laminating, and adhesive purposes. They are known for their strong bonding properties and versatility. Your finished epoxy resin project can be crystal clear which makes it perfect for using with things like:

- Photographs

- Memories

- Flowers

- Glitters

- Sand and shells

- Coloured alcohol ink

- Pigment paste

- Mica powder

Eco Resin

Eco resins can also be used for similar applications as epoxy resins. However, eco resin is solid and opaque in its colour. Before adding eco resin colouring, eco resin will be either white or creamy natural colour once set. You can add:

- Terrazzo effect (little coloured chunks of coloured eco resin)

- Glitter – although results will vary, and it will not be as obvious as with epoxy resin

- Eco resin pigment

Wax can be added to your finished product to add a slight sheen and to ensure it is waterproof.

You can also mix epoxy resin and eco resin together although you need to ensure one resin is fully cured before adding a second layer of your other resin type.

Curing Time and Performance

Epoxy Resin

Generally eco resins have a relatively fast curing time (this will range from a few hours to 24 hours depending on your brand of resin) and provide a durable and glossy finish. They are known for their strength and chemical resistance.

Eco Resin

The curing time and performance of eco resins can vary depending on the specific formulation. Some Eco Resins like JDResinCrete will set to de-mould in 30 minutes or less but will need up to 24 hours before they are ready for a top coat.

Resin Cost

Epoxy Resin

Traditional epoxy resins are widely available and may be more cost-effective due to their established market presence and production scale. There’s many different options and lots of trial products are available in kits but you can up scale to larger containers of resin for relatively low costs.

Eco Resin

As a result of being a relatively new product, eco resins are still somewhat a niche or specialty product. They might be priced higher due to the use of sustainable materials and eco-friendly practices in their production. As they grow in popularity, we are seeing the cost come down and the availability of packet sizes increase.

Always make sure you check out the instructions for the type of resin you choose to buy. Instructions and safety advice will vary a lot between brands.