Epoxy resin can be temperature sensitive. We talk about how to effectively work with resin when it is colder.

Why is epoxy resin temperature sensitive?

Colder resin is thicker

If your resin is cold, it will be more viscous meaning it is thicker. This can make it difficult to pour from your container and get an accurate measurement. If your resin is not correctly measured according to the required ratio, it may not cure fully or could create uneven spots that remain sticky or flexible.

Thicker resin is harder to mix

The more viscous your resin is, the harder it will be to mix your two parts. It can take much longer to mix your resin when it is cold. Good mixing is essential to make sure your resin sets evenly.

Colder temperatures brings humidity

When the temperature drops, you will usually find that the air is more humid. Epoxy resin does not like humidity and if there is too much moisture in your air, you may experience:

– uneven cures

– resin that is not fully cured

– bubbles in your resin (even after initially eliminating them)

– amine blush (a sticky, cloudy or dull appearance to the surface of your resin)

Ideally your humidity levels should be around 50-60% for the best curing conditions.

What can you do when working with epoxy resin in the cold?

Heat your work space

If you’re able to bring your working temperature to a minimum of 20 degrees Celsius / 68 Fahrenheit, this is the ideal minimum room temperature for resin.

A small portable heater like this can be helpful.

Just remember that fans can blow dust so always try and point them away from your resin. Avoid continual hot air over curing pieces too as they can over heat.

Warm your resin

If you store your epoxy resin in a shed of garage where the temperatures are lower, bring your bottles in for at least an hour before using them. This will help raise the temperature of your resin before you mix it.

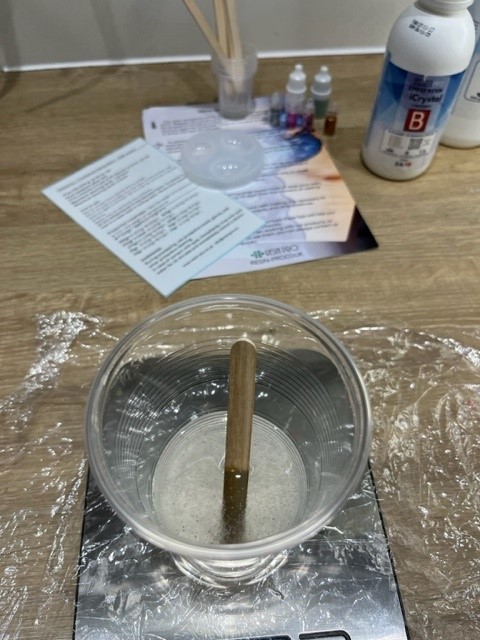

You can also place your bottles of resin (ensuring lids are tightly screwed on so no water gets in) to a bowl of hot, not boiling, water for 10 minutes prior to mixing. This will soften your resin and make it easier to mix your two parts. This can be done each time you go to use your resin. You do not need to use all of the warmed resin in one go.

Pour parts A and B in to cups

Pouring your parts A and B in to separate cups and allowing to warm to air temperature before mixing can help reduce the viscosity and make it easier to stir.

Use a heat mat

Heat mats can be perfect for ensuring your resin is warm enough to cure. They can bring your curing time from 24 hours to only a couple. We use this one from Amazon.

Read our blog on using heat mats for further details on how to get the most out of yours.

Use a resin curing machine

The Resiners Resin Curing Machine will automatically keep your curing resin at the optimal temperature for curing your resin projects fast. You just set the timer and wait.

Let your resin cure in a warm environment

If your workspace isn’t generally somewhere that you would heat or is an area where your temperature drops even more over night, moving your poured resin projects in to a warmer space can help. Remember, do not leave curing resin near pets or children. If your resin is not non-toxic, it should be left to cure in a well ventilated space.