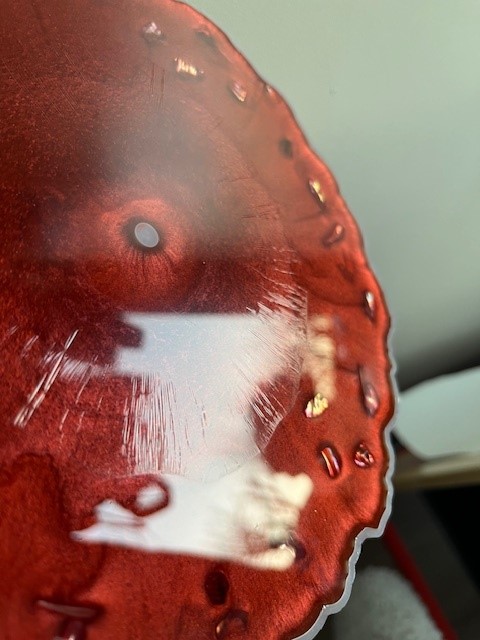

Do you ever get a bumpy, wrinkly skin like top on your resin? It can be so frustrating to see a beautifully made piece ruined by an uneven finish. Sometimes it can be that you’re suffering with amine blush – one of the most common issues you might have when working with Epoxy Resin.

What is amine blush?

Amine blush is a phenomenon that can occur when using epoxy resins. It refers to a waxy or greasy film that forms on the surface of cured epoxy when it reacts with moisture in the air during the curing process. This film can give the epoxy a somewhat oily or sticky feel. Its often bumpy to the touch and I always say, it looks like the skin you can get if you leave hot custard out to cool.

Why do you get amine blush on epoxy resin?

Amine blush is more likely to occur in humid or damp conditions because the moisture in the air reacts with your epoxy resin. Resin and moisture do not mix! Amine blush can occur with all brands of epoxy resin.

What can I do to fix amine blush?

You don’t ever want to give in on a piece you’ve worked so hard on. Its much better to try save your mistakes before you throw them in the bin (even if you might feel like doing that out of despair). So, what can you do to fix amine blush? I’ve tried and tested a few methods that I found after a quick google:

- Washing liquid

I tried using washing up liquid and warm water with a cloth to rub away the imperfections. This did not work. It actually made the amine blush a whole load worse and it became cloudy.

10/10 do not recommend. - Scrubbing

I tried using a pan scrubber with water to see if I could smooth the lines. Again. Nope, did not work. - Alcohol spray

Next up, I tried alcohol spray. After all, it fixes a whole load of other issues with epoxy resin. But it did absolutely nothing. - Resin top coat

I tried pouring a resin top coat directly on top of the amine blush. This worked great but some of the deeper lines were still evident when you got up close. - Sanding

Finally I tried sanding down one of my pieces that had amine blush. I used a fine grit (smooth) sandpaper – 2000 grit and rubbed the whole piece down. I then wiped with alcohol spray and let dry. Then, after pouring another top coat, I eventually saw a really great result. Hooray! The amine blush was gone. This is definitely the route I would go down should it happen again.

How to stop amine blush on epoxy resin?

Amine blush can be fixed but how can you stop it from happening in the first place? It can be really difficult if you work in a country where the weather is changeable. There’s a few things you can do to reduce the chances of humidity ruining your project with amine blush though. Let’s take a look:

Use a dehumidifier

Using a small dehumidifier like this can reduce the humidity in your workspace and reduce the amount of moisture in the air that can mix with your epoxy resin.

Use a heat mat

Using a heat mat can speed up the time it takes for your resin piece to cure. Curing quicker will mean that your resin forms a barrier to moisture quicker. Many like this one also come with a cover which can again protect your piece from moisture in the environment.

Avoid working in storms / rain

Bad weather inevitably brings moisture in the air. If you avoid working with epoxy resin when there is a big storm or rain due will reduce the risk of your piece getting amine blush.

Read our blog on how to work with epoxy resin when it’s cold.

Thanks for the info do I need to sand all the way down to the bare wood or just sand the surface a bit and then pour another coat

Lightly sanding just the top until smooth should be sufficient.